Pcb Uses

Pcb stencil, also known as steel mesh, its main function is to help solder paste deposition and transfer an accurate amount of solder paste to an accurate position on the bare pcb. Every industry is affected by them on some level in our day to day activity.

Electronics Board Manufacturing

This page provides the agency's updated guidance for school administrators and building owners, including.

Pcb uses. The environmental protection agency today issued final regulations banning the manufacture of polychlorinated biphenyls (pcbs) and phasing out most pcb uses. Typical industry applications of pcb leds include: Pcb chemicals were banned in the u.s.

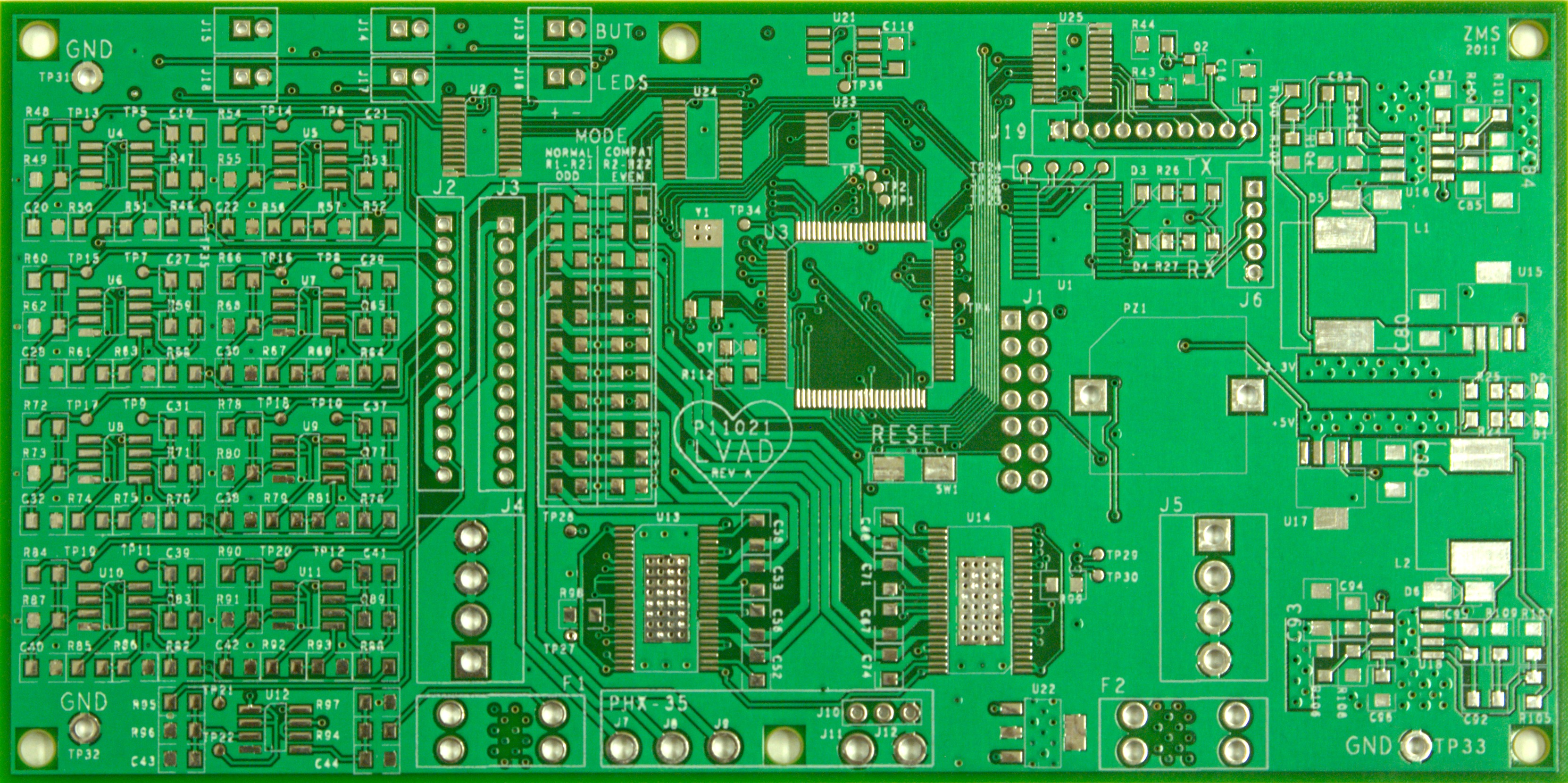

They're used as physical support for mounting and wiring different electrical components. As pcbs are resistant to acids and bases as well as to heat, they have been used as an insulating material in electric equipment, such as transformers and capacitors, and also in heat transfer fluids and in lubricants. Pcbs were also sprayed on dirt roads to.

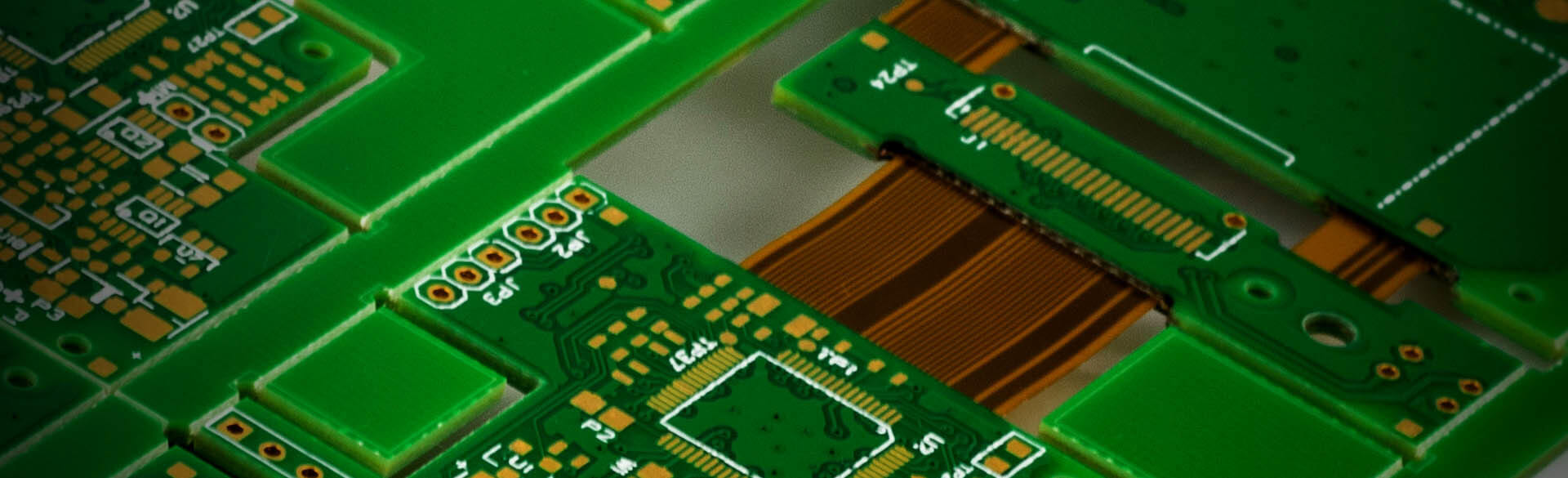

Pcbs are most commonly made out of fiberglass, composite epoxy, or another composite material. Electrical equipment heat transfer equipment hydraulic equipment plasticizers plastics rubber pigments dyes flame retardants adhesives pesticide extenders. In these instances, prototyping and testing connectors make a great substitute, allowing you to make changes on the fly without having to resolder things to a pcb.

What is a pcb stencil and how to use it? Pcb can be used to create prototypes, do product development, and even make finished products. Potential sources would be facilities which used, stored, and serviced electrical equipment and which used significant amounts of electricity.

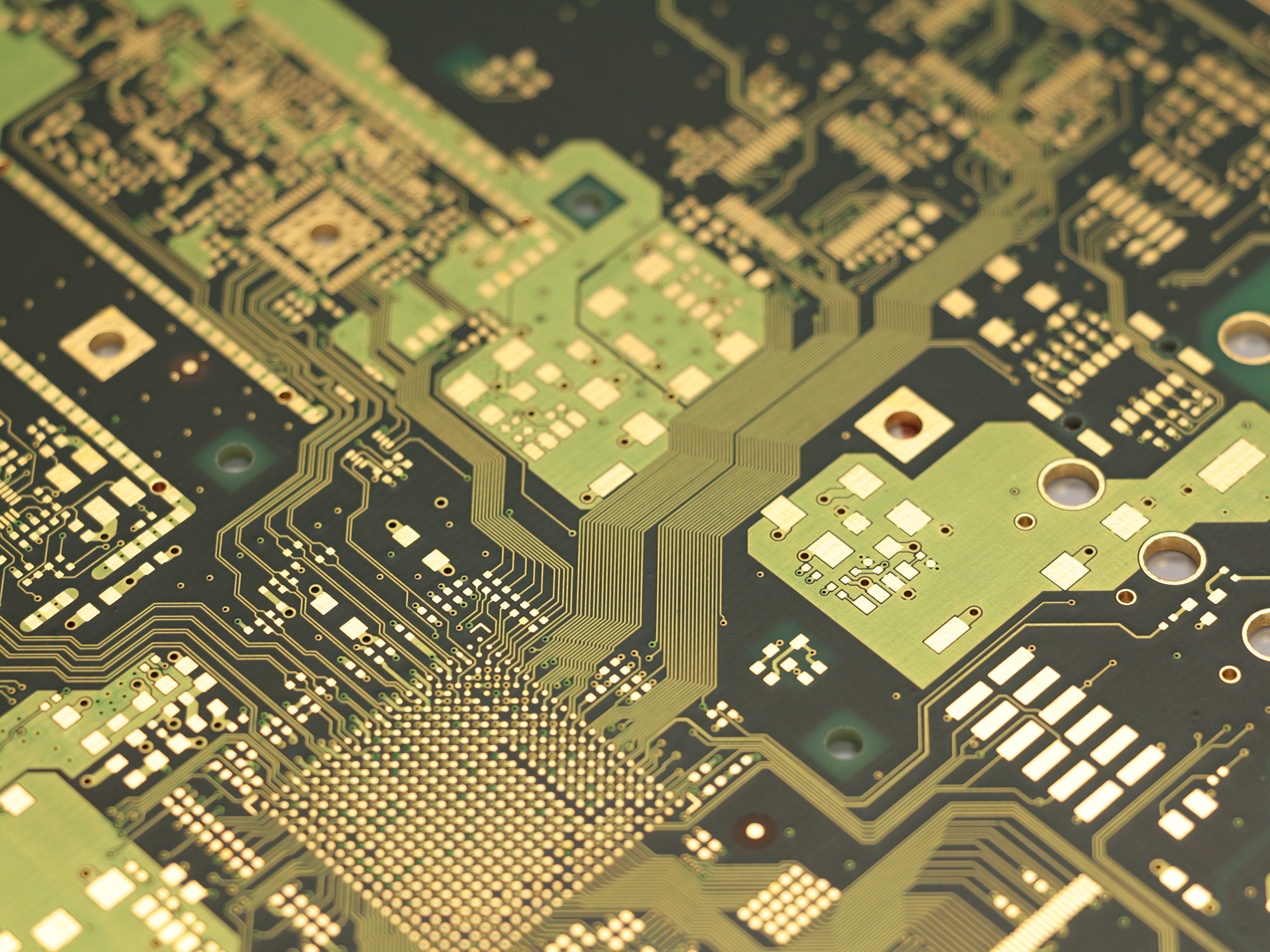

Polychlorinated biphenyls (pcbs) in building materials. Pcb containing caulk is not totally enclosed and is thus not authorized. The fabrication data is read.

Pcbs may only be used in a totally enclosed manner unless authorized under 40 cfr 761.30 note: Automotive (indicators, headlights, brake lights, etc.) Manufacturing starts from the fabrication data generated by computer aided design, and component information.

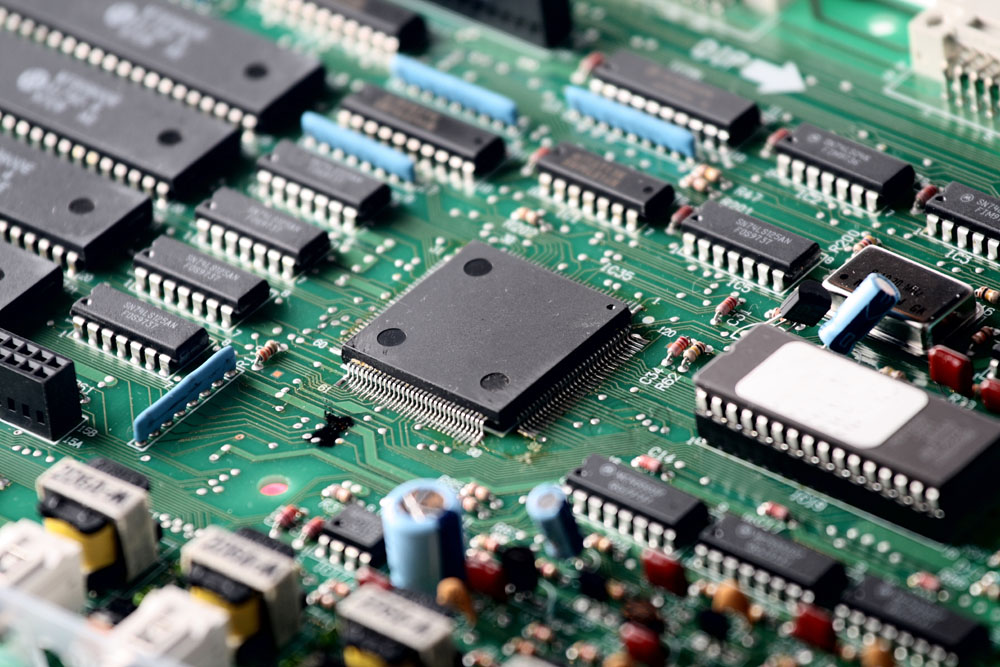

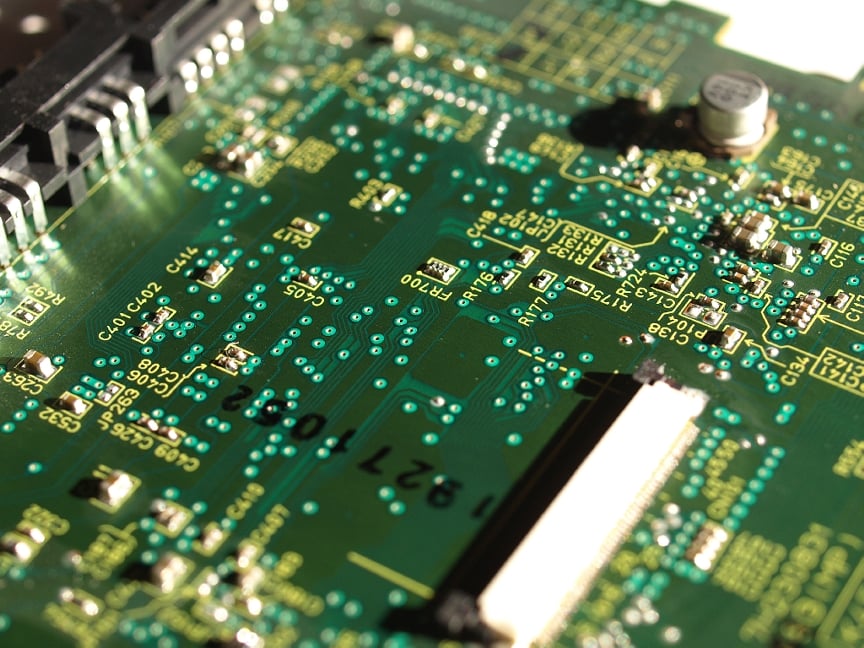

Printed circuit boards (pcb's) are convenient thin boards used for housing interconnecting electrical components in a simple, convenient and economical way. There are many holes in the stencil, and the positions. In 1979 because these chemicals harm human and environmental health.

They're in boats, planes, phones, and of course our computers. The future of pcb production is uncertain and will depend on the success of 3d printing technology. The stencil is composed of stencil frame, wire mesh and steel sheet.

Because pcbs are highly stable and insulating, they served as ideal chemicals for many different industrial and commercial uses, including: Even fighter jets and night vision goggles use pcb. From the 1920s until their ban, an estimated 1.5 billion pounds of pcbs were made for things such as microscope oils, electrical insulators, capacitors, and electric appliances such as television sets or refrigerators.

You'll find these being used on electronic test equipment like multimeters and will include one or multiple banana jack connectors.

RigidFlex PCB PCB Assembly,PCB Manufacturing,PCB design

Single and MultiLayer PCBs Know the Difference

What is the function of integrated circuit? TOP10 PCB

PCB Manufacturing Process A Complete Guide For Beginners

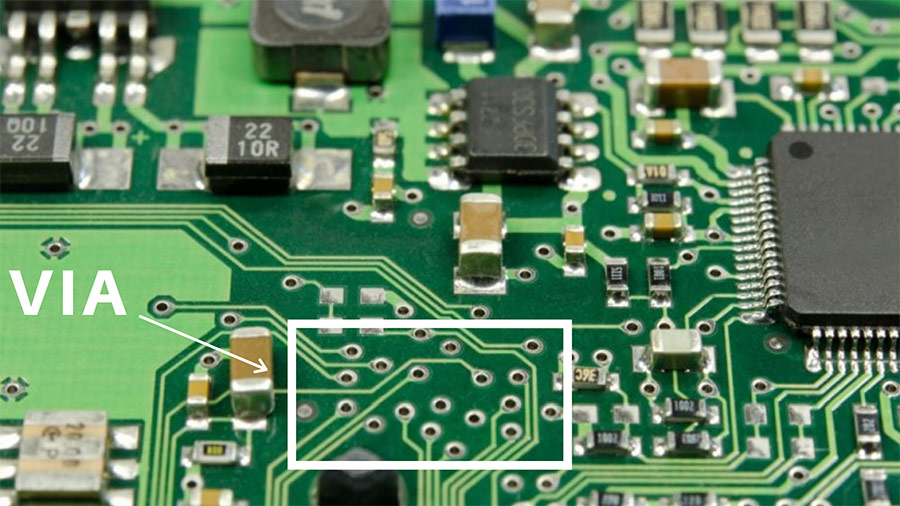

What is Via in PCB design and how to use them Gadgetronicx

Use All That Extra Space With PCB Panelization Hackaday

Tips For Efficient HDI PCB Electronics Manufacturing

5 Reasons To Use A PCB Assembly Partner

PCB stack Custom Design Technologies CDT

The development trend of latest PCB boards technology in

Know these Pros and Cons before Using Printed Circuit

PCB laminate considerations for 4Gbased M2M designs

Standard PCB and HDI applications Limata

PCB Design Terminology You Should Know Tempo

PCB Design Tips 5 NeedtoKnow Component Assembly Methods

Should I Use Lead Free PCB Assembly? Tempo